Customers of your supply chain order products in accordance with their demand. In the Demand table you define the mechanism of how the customer's demand for the product is formed.

By default demand is generated on the first day of the first period. In the following cases demand will be automatically set to Next day after interval:

- The imported scenario was created in the older version

- The outdated database is updated to the new version. This affects all scenarios of this project.

| Column | Description |

|---|---|

|

Customer |

Defines the customer. The cell contains a list of customers (defined in the Customers table). |

|

Product |

Defines the product for which the demand is specified. The cell contains a list of products (defined in the Products table). If you generate scenario with 2 or more products, this column will be set by default to the newly created Generated products group for every customer. |

|

Demand Type |

Type of demand definition:

The cell contains a drop-down list with the demand types. |

|

Parameters |

Defines the demand data. For more flexibility, you can set these parameters to be of stochastic nature. In this case, they will vary in accordance with the certain probability distribution. More details on how it affects demand. Demand occurrence does not depend on the experiment start date Periodic demand parameters:

Periodic demand with first occurrence parameters:

Historic demand parameters:

Learn how to define demand parameters. Learn more about constraints and penalties. |

|

Time Period |

Defines the period of time (previously defined in the Periods table) for the demand specified in Parameters. The cell contains a list of available periods. |

|

Revenue |

Allows you to set selling price for product. It might be as well used for selling the same product for a different price to a certain customer. If specified, the value will override Selling Price defined in the Products table The specified value can be overridden by Price (per unit) defined in the Sale Batch table |

|

Down Penalty |

Defines the penalty to be paid per product item for violating the specified demand Quantity (defined in the Parameters column).

If the penalty is set to 0, the specified Quantity will be considered as a hard constraint, i.e., it cannot be violated. In other cases the Quantity is treated as a soft constraint. For more information refer here. |

|

Up Penalty |

Defines the penalty to be paid per product item for violating the specified demand Quantity (defined in the Parameters column).

If the penalty is set to 0, the specified Quantity will be considered as a hard constraint, i.e., it cannot be violated. In other cases the Quantity is treated as a soft constraint. For more information refer here. |

|

Currency |

The type of currency in which the Revenue is expressed. In case of Network Optimization scenario type, this also refers to Down Penalty and Up Penalty. |

|

Expected Lead Time |

Defines the time period (in time units specified in the Time Unit column) within which the ordered product is expected to be received by the customer. The value is used to calculate the ELT service level statistics. |

|

Time Unit |

Specify the time unit, in which the Expected Lead Time is expressed. The list of available units comprises the units defined in the Manage units dialog. |

|

Minimum Split Ratio |

If a non-default value is specified in the interval between 0 and 1 (greater than 0 and less than 1), a customer will allow orders to be split for partial shipping, if required. This solution is used to prevent order delaying when there is insufficient inventory. In this case the order will be sent in parts (the minimum size of each part is defined by the value specified in this cell). See the example for detailed explanation. |

|

Backorder Policy |

Defines the backorder policy for the selected product and customer. The backorder policy defines how the order is handled in case the required number of products is not yet available for shipping. There are two alternative options:

|

|

Inclusion Type |

Defines the status of the given demand.

|

Once the demand has occurred on a random day of the order interval, it is then scheduled to occur according to the defined Order interval parameter (e.g. in 5 days).

Depending on scenario type the Random option will set:

- A random day within the Order interval in case of a SIM scenario type. The next time the demand will occur in 5 days (in case of the default value of the Order interval parameter).

-

A day in the middle of the Order interval in case of GFA, NO, type of scenarios.

E.g. If the order interval is 5 days, the demand will occur on day 3. The next time the demand will occur in 5 days.

If you add stochastics to periodic demand, the demand will be processed in the following way:

- For the SIM scenario type a certain amount of product (within the range defined in the Quantity parameter) will be ordered on a certain day within the period defined in the Order interval parameter.

-

For the GFA and NO scenario types it works like this:

-

First, the actual demand is defined within the range specified in the Quantity

parameter.

E.g. The average of 10 items will be taken if we set Quantity parameter to 5-15 items (uniform distribution).

-

Then we check how many Order intervals fit into the period defined in

the Periods table.

E.g. The Order interval is set to 10 days and the Periods table contains 12 periods (one period per month). The first period is January (31 days). In this case we have 31 / 10 = 3.1 order intervals in January.

- Now we estimate the overall demand per period, which is calculated as items demanded per order interval * number of intervals in the first period or 10 * 3.1 = 31 item

-

First, the actual demand is defined within the range specified in the Quantity

parameter.

By default the experiment start date coincides with the scenario start date, but you can change the experiment duration by setting any other start/end dates. This will not affect the initial demand occurrence schedule as it is based on the scenario start date.

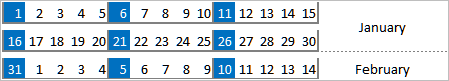

Below you can see how it works with the default demand settings:

- First occurrence is set to First day

- Order interval, days is set to 5 days

- Quantity is set to 10

Demand occurs on the first day of the scenario (which is the same first day in the period and the ordering interval). Later on, the demand occurs every 5 days, i.e., on the first day of every succeeding order interval (marked blue).

If we decide to start the experiment from any other date, this schedule will not change. The estimation of the demand occurrence will remain the same, since the Order interval is calculated from the scenario start, not the experiment start.

E.g. if we start the experiment from February 1st, the demand will occur on February 5th and not on February 1st.

-

How can we improve this article?

-